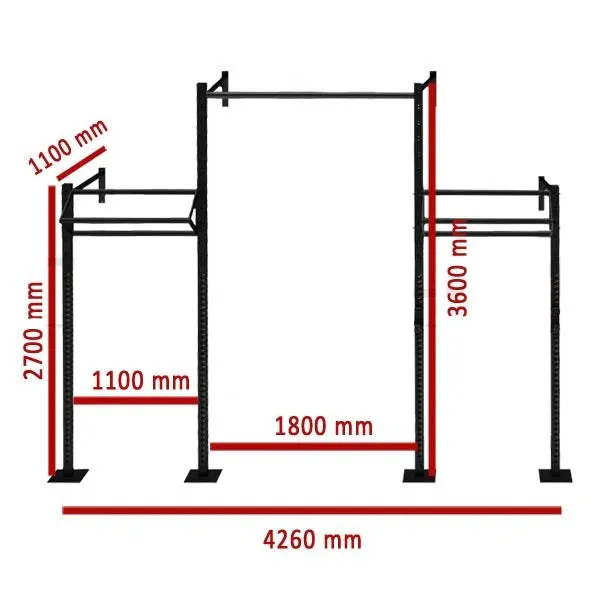

PRODUCT SPECIFICATIONS

- Cell spacing for barbells (squats, bench press etc.) is 1100mm.

- Cell spacing for chin ups, gym rings, Trx, climbing rope etc is 1800mm.

- Adjustable Pull-up Bar.

- Uprights are laser cut on all four sides to maximise configuration and attachment options so you get the most out of your training space.

- Hard wearing black powder coating finish.

- Dimensions when assembled: 4260mm(L) x 1165mm(W) x 3600mm(H).

- All Rigs must be bolted to the floor.

COMPONENTS

- 2 x 2700mm Uprights. Additional 3600mm (12Ft), 2700mm (9Ft) and 3250mm (8Ft) uprights are also available.

- 2 x 3600mm uprights for High Extension Cross Beams for battling rope or high gym ring extension.

- 2 x 1100mm Triangular Chin Up Cross Beams providing 2 Chin Up Stations

- 1 x 1800mm Single Cross Beams

- 4 x 1100mm Single Cross Beams providing 2 Chin Up Stations

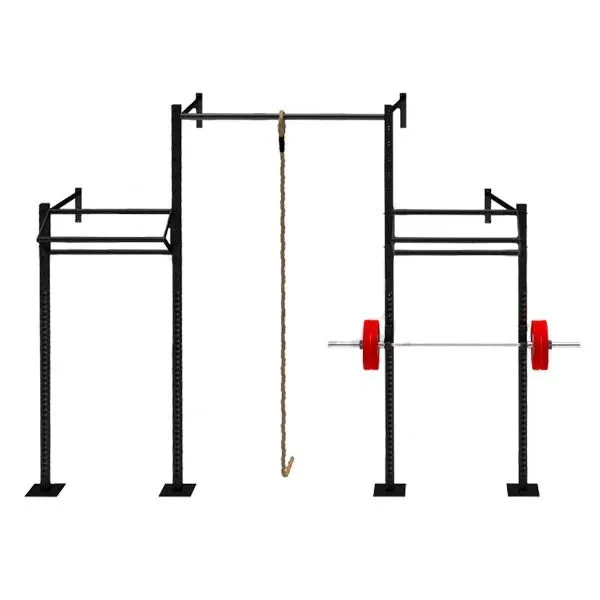

- 2 x Pairs of Titanium USA Premium J Hooks

WORKOUT STATIONS

- 2 x Bench Press with Squatting Stations.

- 4 x Chin Up Stations.

- 1 x High Extension Cross Beams for climbing ropes and gym rings.

RIG CUSTOMISATION

Whether you’re looking for small functional training set up or complete gym fit-out, this Titanium USA™ rig can be completely customised depending on your space, budget and training requirements.

- Custom made uprights to maximise space and height restrictions.

- Multiple options for Cross Beams from single, double and triple chin up bars of different lengths.

- Choose from one cell to ten or more depending on the size of your facility. You can also add on more cells as your business grows.

- Rigs can be finished off with your company logo if required.

- Rigs can be made with 110 cm or 180 cm cross beams or even made to order if you have a specific size you are after.

- Width or depth of Free Standing and Wall Mounted Rigs can be made to order.

- Cross Beams and Chin up bars can be adjusted to multiple heights.

Titanium USA™ rigs have been manufactured using premium quality steel tubing and are designed to withstand enormous punishment in any Gym, Crossfit Facility, Functional Fitness Centre or Elite Sports Club.

All uprights are numbered for hassle free adjustment of J Hooks and Spotter Arms, to prevent wasted time during change over and to ensure they are matching at the correct positions, so you don't have barbells set at incorrect levels. Also, rather than printing, stamping or painting the numbers on the uprights, we have taken it to the next level by using cutting edge technology to laser cut numbers on 2 sides of the uprights. Numbers that are painted or printed on uprights will eventually rub off and look unsightly over time. Laser cutting the numbers into the steel ensures your rigs will look great no matter their age.

All adjustment holes on our uprights are also laser cut on all four sides to maximise configuration and set-up options for J Hooks and Spotter Arms, Dip Handles, and other attachments. Most manufactures use a hole punch machine to punch out the holes on the uprights. Punching holes is the cheapest and roughest way to cut out holes in uprights, but this causes the steel to bend inwards and does not produce a clean hole. Not only this but it usually leaves behind rough edges and shards of metal still attached to the holes, which weakens the overall strength and integrity of the uprights. Laser cutting the holes requires precision engineering and provides the ultimate finish during the manufacturing process of the uprights.

Call 1800 006 526 or email [email protected] to discuss what options are available for a custom built rig to meet your needs.

Cart(

Cart(